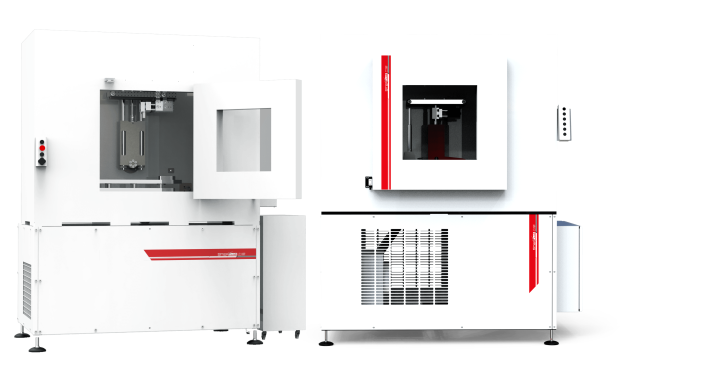

A dynamic mechanical test module for testing products at the end of the assembly line, our software is organised to be easily adapted to each type of activity according to the main international standards. The programme is organised to offer you editable presets of the most common tests or allow you to quickly customise your test. Our systems have been mounted on shock absorber and solenoid production lines.

Shock absorber testing

Solenoid test

Custom

End-of-line test management

It meets a full spectrum of performance, durability and quality assurance testing needs with STEP Lab’s comprehensive portfolio of custom test software. Designed to support any interaction with assembly line systems, these programmes offer comprehensive test creation, efficient runtime and data acquisition, automated reporting and numerous methods for presentation and analysis.

Dynamic characterisation

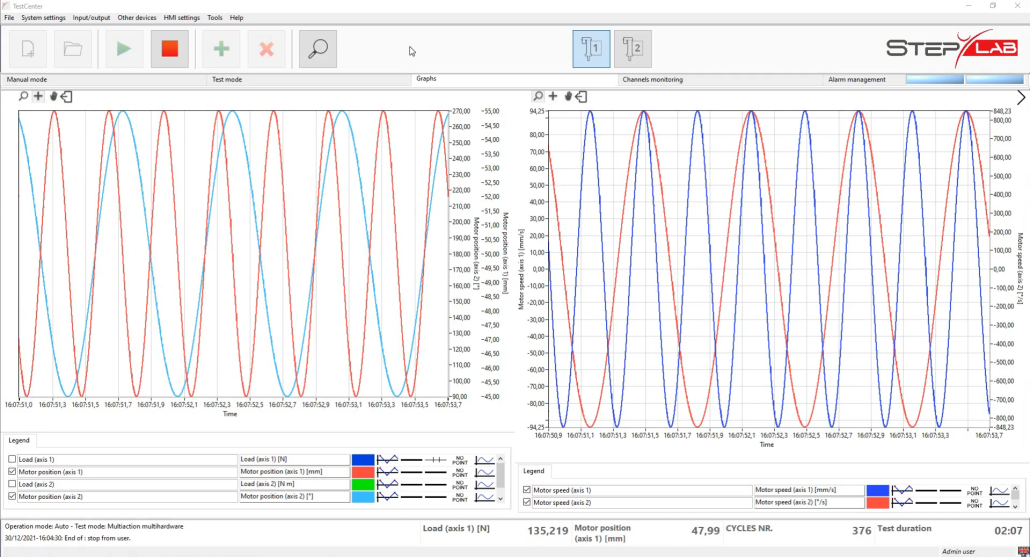

Use the Test Result Selection window to choose between different ways to collect data during the test, select upper and lower limits for each test result and define how the results are reported.

Use the pop-up data displays to review the current test, view curves for the last performance phase, show cycle counts and monitor sample temperature;

It conducts dynamic characterisation of viscoelastic materials or components over a wide range of variables with up to four simultaneous control channels.

- PWM channel management for active dampers.

- Measure dynamic stiffness (K), phase angle, damping (C), modulus (E or G), delta tan

- Performs frequency, dynamic amplitude, and average level characterizations on systems with a single dynamic channel

- Scan individual variables for average level, dynamic amplitude, frequency, temperature, or phase relationship between control channels

- Combine several scans in one test

- It performs phase-dependent characterizations between dynamic channels on systems with more than one dynamic channel.

- Performs characterisations as a function of temperature set point

- Includes automatic measurement and correction of dynamic system errors induced by transducers and electronics

Quality Control

A software extension for the dynamic environment, characterised by a simple user interface.

- Compare calculated parameters with predefined limits for quality control applications

- Send pass/fail data to a part file or COM port and indicator lights

- Can select data to be displayed during batch test operation and archived for post-test analysis

- Includes macros for Microsoft Excel that calculate basic statistical information

Testing for shock absorbers

Developed for damper production environments, EOL software provides efficient configuration and runtime of speed-based tests, easy identification of sample failures and a variety of methods to graphically represent and report results.

EOL functionality:

- Set parking, test and pick-up positions and define customised pre-cycles and speeds

- Conducts gas force tests (including user-configurable upper/lower limits and waveform points)

- Defines up to three different test speeds at various cyclic amplitudes

- Predefines operational limits or calculates them from the statistical average of the parts in a new batch run

- Displays diagnostic data on a user-configurable screen with fault indication

- Adds data to existing batches or collects and analyses in new batch files

- Performs statistical analysis at the end of each batch file