STEP Lab is specialized in the production of biomedical testing equipment designed to subject medical devices to comprehensive testing in accordance with global standards and regulations, including ISO 10328.

WHAT IS ISO 10328?

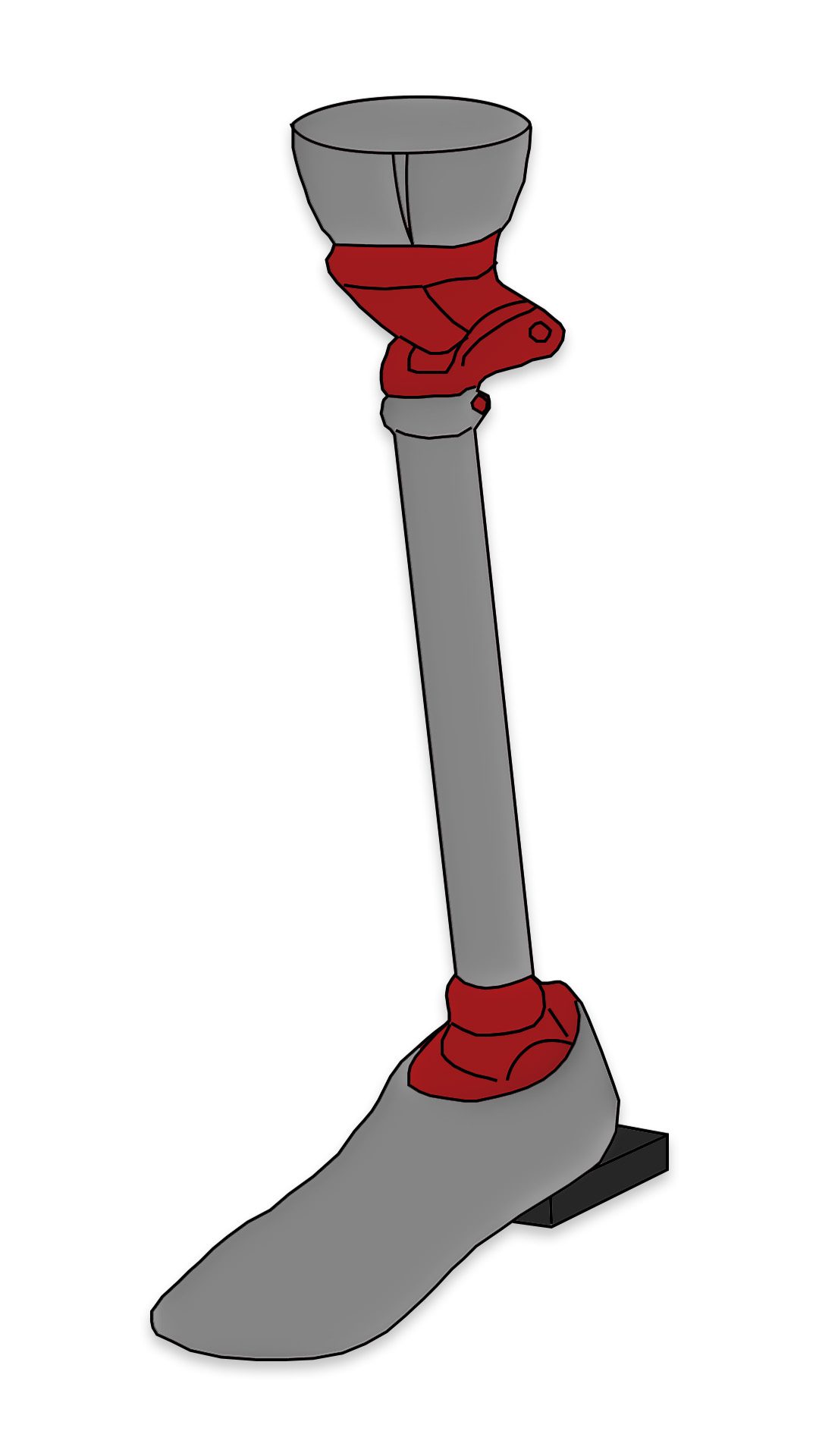

ISO 10328 is an International Standard that provides guidelines for evaluating the conformity of lower limb prosthetic devices and structures with the strength requirements specified in ISO 22523. It states that prosthetic ankle-foot devices and foot units that have already demonstrated compliance with the strength requirements through ISO 10328 tests are exempt from retesting according to ISO 22675.

ISO 10328 – TESTING PROCEDURES

The International Standard ISO 10328 outlines procedures for conducting static and cyclic strength tests on lower limb prostheses. These tests involve applying a single test force to generate compound loads, simulating the maximum load values experienced by different components during the stance phase of walking.

- For the cyclic fatigue test, the specified number of cycles is 3×10^6.

ISO 10328 – DIFFERENT TESTS

ISO 10328 covers several different tests, such as:

- principal static and cyclic tests for all components;

- separate static torsion tests for all components;

- separate static and cyclic tests for ankle-foot devices and foot units;

- a separate static ultimate strength test in maximum knee flexion for knee joints and associated parts;

- a separate static and cyclic tests on knee locks for mechanisms that lock the knee joint in the extended position.

ISO 10328 – TYPES OF PROSTHESES

These testing procedures are applicable to specific types of prostheses, such as ankle-disarticulation, transtibial (below-knee), knee-disarticulation, transfemoral (above-knee), as well as the distal parts of hip-disarticulation and hemi-pelvectomy prostheses.

TESTING MACHINES FOR ISO 10328

Our EA dynamic and fatigue testing machine is a versatile solution for conducting tests that require high accuracy and speed in both force and position control.

-

- Dynamic loads range up to 200kN

- Zero maintenance and easy installation

- Low energy consuming

- Highly reliable test